Products

PCB Dust-free Prepreg Automatic Cutting Machine

Five Advantages Of Products

- Technical Innovation: The first company to adapt infrared preheating technology in prepreg cutting.

- Low dust, environmental friendly: Preheating then cutting, automatic sealing side without drawing; increase the dust collection device, through the detailed calculation and analysis of fluid, reduce dust, environmental friendly and healthy.

- Precision: Using high precision actuator and synchronous servo control system, high cutting precision.

- High quality: Cut the Pre-preg neatly, automatic edge banding, no drawing.

- High efficiency:Dynamic heating transverse, longitudinal cutting, improve cutting efficiency; After cutting, the PP sheet can be used directly without subsequent sealing side, vacuuming, etc.; The precision and efficiency of the cutting are further improved; PP sheet can be automatically stacked; Parameters can be packed up and brought up directly.

Product Details

Dust-free Prepreg Automatic Cutting Machine

USAGE

The equipment is used for cutting rolled prepreg, to solve the problems of prepreg spreading and too much dust in cutting and after cutting so as to improve the cutting accuracy, quality and efficiency.

CHARACTERISTICS

1. Technical Innovation: The first company to adapt infrared preheating technology in prepreg cutting.

2. Low dust, environmental friendly: Preheating then cutting, automatic sealing side without drawing; increase the dust collection device, through the detailed calculation and analysis of fluid, reduce dust, environmental friendly and healthy.

3. Precision: Using high precision actuator and synchronous servo control system, high cutting precision.

4. High quality: Cut the Pre-preg neatly, automatic edge banding, no drawing.

5. High efficiency: Dynamic heating transverse, longitudinal cutting, improve cutting efficiency;

After cutting, the PP sheet can be used directly without subsequent sealing side, vacuuming, etc.;

The precision and efficiency of the cutting are further improved;

PP sheet can be automatically stacked;

Parameters can be packed up and brought up directly.

TECHNICAL PARAMETER

ITEM CQ2000 CQ2000C CQ3000C

Cutting Accuracy ±1mm

Quality Compared with the traditional purely mechanical cutting. Tidy cutting edge,

no white edges & layered & wrinkled and charred carbonation.

more than 95% more than 98% dust reduced

dust reduced

Cutting frequency ≦21 times/min ≦23 times/min

(take 500mm length

as calculation)

Objects Cutting Length 250mm~750mm

Cutting Width 200mm~1270mm

Cutting Thickness 0.02mm~0.3mm

Slitting Circular Knife Shear Type/Cut Type; Continuous Uninterrupted Feeding;

Cut Type

Pointing knife adjustment Manual Manual Automatic

WEHANS AUTOMATION TECHNOLOGY. CO., LTD

Contact Person: Cynthia

Telephone: +86 15062667823

Landline: +86 18121053868

Company Address: Building 1, No. 268, Dengyun Road, Yushan Town, Kunshan City, JIangsu Province, China.

Website: www.wehans-tech.com

Previous: PCB Legend Inkjet Printer (PY800I)

-

Multi-channel intelligent digital eddy current detector EIG3000

-

Multi frequency& multi-channel intelligent digital eddy current detector EK3000

-

Multi-channel intelligent digital eddy current detector EIG2000

-

Intelligent digital eddy current material sorting instrument ERS6000

-

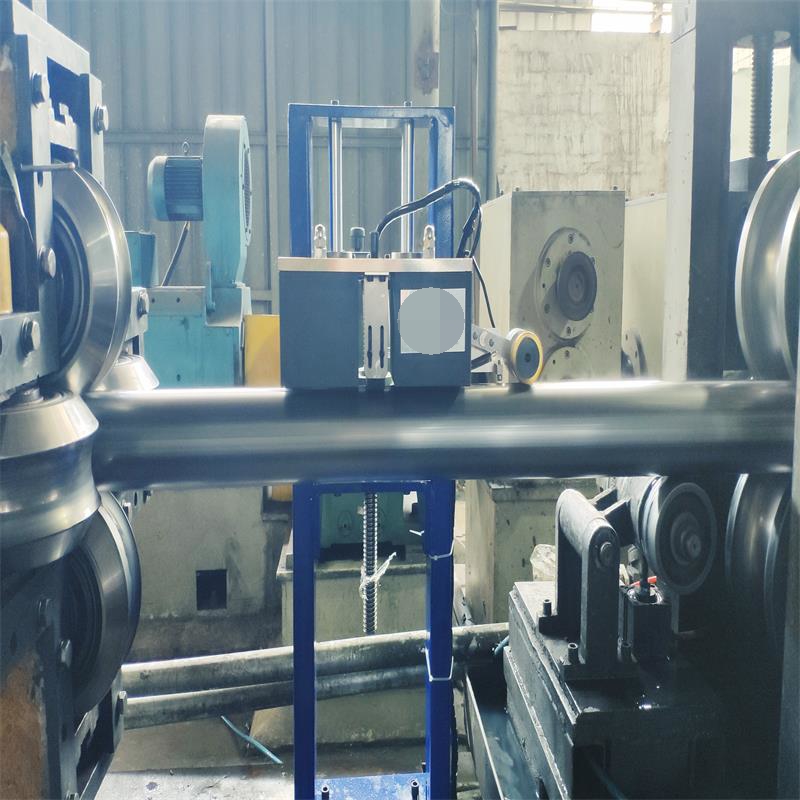

On-line eddy current testing system for stainless steel straight welded pipe ECN1002/EFN1002

-

On-line eddy current testing system for straight welded pipe EFH1002

-

On-line eddy current testing system for spring steel wire ECH7002

-

PCB Metallographic Microscope (JX22/JX23-RT)