Products

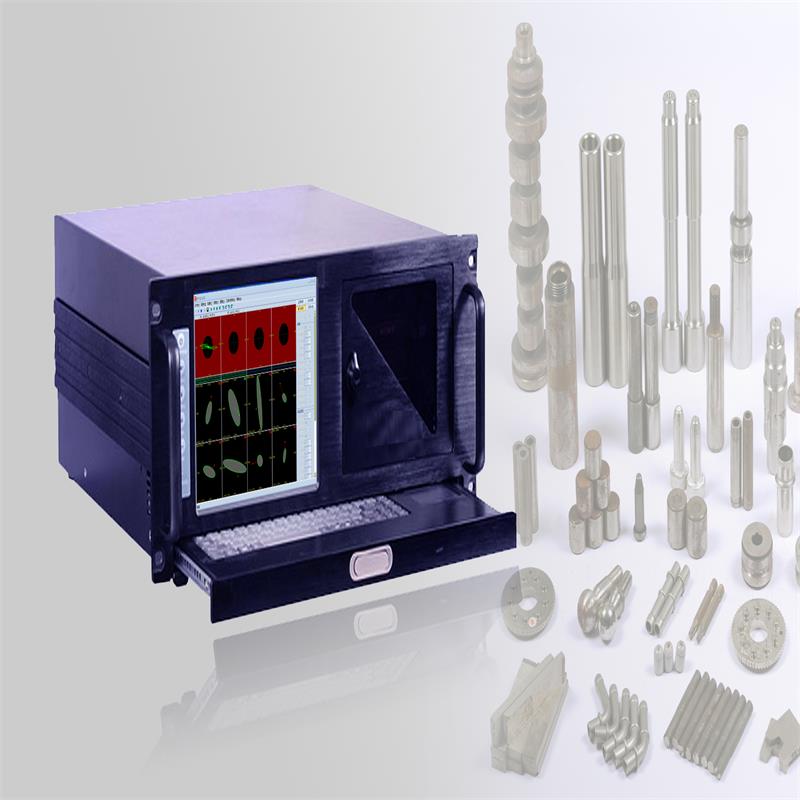

Multi-channel intelligent digital eddy current detector EIG3000

Five Advantages Of Products

- The MSUN-EIG3000 series multi-channel detector is digital, intelligent and highly integrated.

- The system adopts the most advanced microcomputer electronic technology, DSP digital processing technology and FPGA technology to develop and design.

- With powerful data input/output capabilities, it can connect to most of the world's automation systems.

- The new software algorithm, better detection performance and higher noise-to-noise ratio than the peers, continuous software development, providing free software upgrades for life.

- The instrument can be equipped with high-precision automation matching module, magnetic saturation device, marking system and alarm system to realize automatic eddy current detection.

Product Details

Multi-channel intelligent digital eddy current detector

Highly integrated and high performance intelligent digital eddy current detector

◆The MSUN-EIG3000 series multi-channel detector is digital, intelligent and highly integrated. The system integrates an independent 1-8 channel eddy current detection system with powerful detection and experimental functions, good stability and high noise-to-noise ratio. At the same time, it can expand a variety of practical application functions (hardness sorting).

◆The system adopts the most advanced microcomputer electronic technology, DSP digital processing technology and FPGA technology to develop and design. Based on the development of WINDOW system. Based on the system detection platform, the detection signal and data can be shared in multiple aspects, and the functions of data acquisition, output, analysis, storage, and reading are intelligently processed.

◆With powerful data input/output capabilities, it can connect to most of the world's automation systems.

◆The new software algorithm, better detection performance and higher noise-to-noise ratio than the peers, continuous software development, providing free software upgrades for life.

◆The instrument can be equipped with high-precision automation matching module, magnetic saturation device, marking system and alarm system to realize automatic eddy current detection.

◆Powerful software features include parameter storage, data storage, report analysis, statistics and more.

◆It can be equipped with coils of various structures with low clearance requirements (the selection of probes can be completely determined according to the user's testing requirements), and it can flexibly and quickly customize various high-performance and cost-effective detection probes (point type)., flat, inner wear, outer wear, saddle, rotary sweep, sorting and other probes).

◆The instrument is simple, reasonable and intuitive to operate.

◆Quickly switch between Chinese and English with one button, and quickly customize multi-language packs.

◆The system can be widely used in nuclear power, petrochemical, metallurgy, university teaching, automation enterprises, auto parts manufacturing, various laboratories and other industries.

Technical Specifications

◆Detection channel: 1-8 (sustainable expansion as needed)

◆Frequency range: 10 Hz~12MHz, continuously adjustable; multiple independent frequencies, single frequency, 8 frequency options (up to 16 software frequencies per channel);

◆The system is based on WINDOWS development, and the system is permanently upgraded for free;

◆Gain range: 0.0dB~99.0dB continuously adjustable, stepping: 0.1dB; fine-tuning, fast increase/decrease;

◆Gain ratio: (X/Y) 0.1~10.0; continuously adjustable, fine-tuning, fast increase/decrease;

◆Signal to noise ratio≥10dB (up to 30db);

◆Phase rotation: 0~360° continuously adjustable, stepping: 1;

◆Adjustable probe drive (excitation) level: 1 to 16;

◆Filter coefficient: 0-30000;

◆Adjustable detection range, ie maximum measurement value: 10~10000, step 1;

◆Hardware amplification factor: 1dB~32dB continuously adjustable, step: 1dB;

◆Multiple excitation modes: DP/DI; can be configured with differential, absolute and various custom probes

◆Probe abnormal alarm function (viewing model)

◆Fast digital balance;

◆The solid line and blanking display modes are flexible and optional;

◆Blanking display coefficient: 1~400;

◆Digital filtering: low-pass (0Hz~2000Hz) high-pass (0Hz~2000Hz); using a unique "digital filtering" to effectively suppress the on-site interference signal, to ensure the accuracy and stability of the detection;

◆Stability: 16 hours≤2dB;

◆The utility model has the function of cutting off the end and end tail signals, and effectively controlling the end dead zone of the end end;

◆The alarm duration can be adjusted: 10ms~60000ms, stepping 1ms;

◆Missing rate:≤0%, false positive rate (falsely judged as a non-conforming product by mistake)≤1%;

◆Provide accurate and timely feedback signals to the defect parts, and perform inkjet marking, marking position, length, etc. (requires peripheral support);

◆Automatically record the number of defects and their locations;

◆With delay marking, fixed length marking, delay alarm and other functions;

◆Flexible internal and external clock selection;

◆Marking accuracy up to ≤±10mm (requires peripheral support, depending on detection speed, requirements);

◆Real-time software/hardware output alarm, multiple alarm window modes (circular, square, fan-shaped, custom type), with alarm, pre-alarm function, and can output signals separately;

◆Non-equal amplitude, asymmetric phase alarm zone setting;

◆Multiple display modes: impedance, time base, AB sweep, 8 frequency sorting, analog 3D display (depending on model selection);

◆With a unique time base alarm reference line, more intuitive detection data display;

◆Can store a large number of various detection programs and test data;

◆The eddy current signal playback extension function can measure the amplitude, phase and digital value of the defect;

◆Cartesian coordinate system and polar coordinate system background selection;

◆Automatically form test reports (including the number of tests, test personnel, test parameters, number of pass and number of non-conformities, etc.);

◆One-click switching between Chinese and English operating languages, no need to install an operating system or online help;

◆Power supply: AC 220V/110V;

◆Working temperature: 0°C~+45°C, storage temperature: -20°C~+50°C, relative humidity: ≤85%;

◆The plane for installation of each flaw detector is: 550×1000mm2, and the signal line can be either side wall or bottom.

◆Appearance size and weight: 500*500*180mm (L*W*H), weight: 5kg (without display)

◆Optional small industrial control type, horizontal industrial control type, 5U industrial control type (with display)

WEHANS AUTOMATION TECHNOLOGY. CO., LTD

Contact Person: Cynthia

Telephone: +86 15062667823

Landline: +86 18121053868

Company Address: Building 1, No. 268, Dengyun Road, Yushan Town, Kunshan City, JIangsu Province, China.

Website: www.wehans-tech.com

Previous: Multi frequency& multi-channel in...

-

Multi-channel intelligent digital eddy current detector EIG3000

-

Multi frequency& multi-channel intelligent digital eddy current detector EK3000

-

Multi-channel intelligent digital eddy current detector EIG2000

-

Intelligent digital eddy current material sorting instrument ERS6000

-

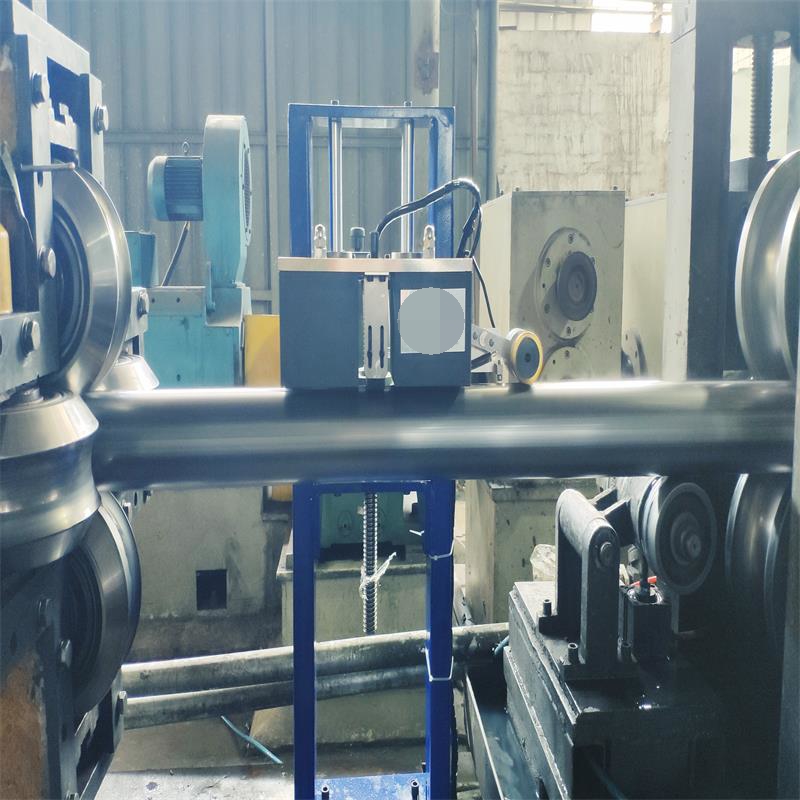

On-line eddy current testing system for stainless steel straight welded pipe ECN1002/EFN1002

-

On-line eddy current testing system for straight welded pipe EFH1002

-

On-line eddy current testing system for spring steel wire ECH7002

-

PCB Metallographic Microscope (JX22/JX23-RT)