Products

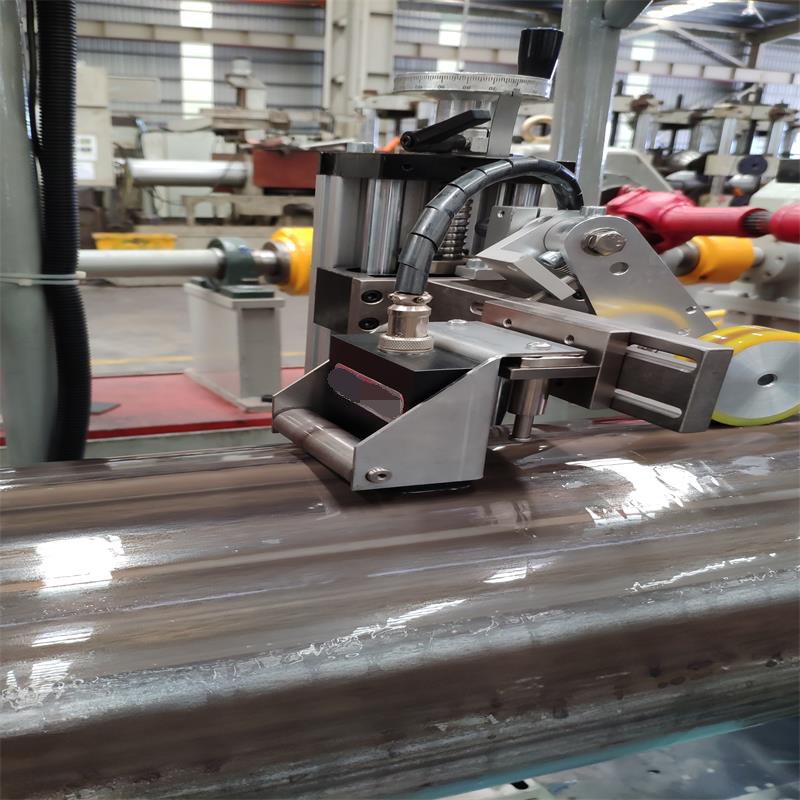

On-line eddy current testing system for straight welded pipe EFH1002

Five Advantages Of Products

- Adjust the technical parameters and standard samples of flaw detector according to the testing requirements.

- Adjust the position of probe and probe according to workpiece specifications.

- The flaw detection system detects the workpiece, alarms and marks.

- The welding head can be ground or adjusted by shutdown during the process.

- Data recording, storage and analysis are carried out by the flaw detection host.

Product Details

On-line eddy current testing system for straight welded pipe EFH1002

Project Overview

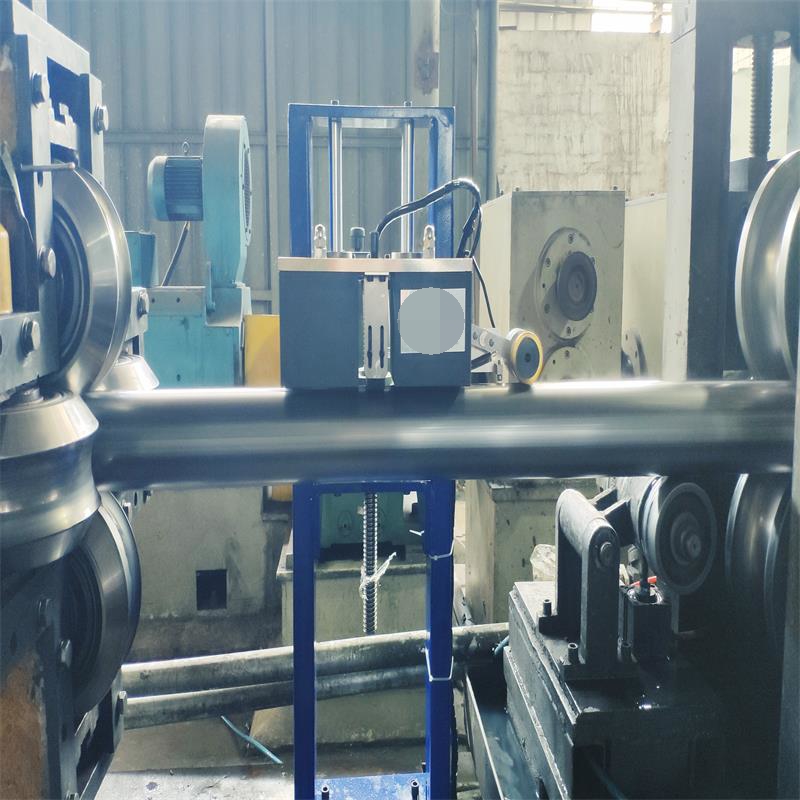

Customers produce high frequency welded straight welded pipes, which are made of ferromagnetic materials. On-line eddy current automatic flaw detection system is installed in the field. Testing requirements: to detect transverse and longitudinal defects of pipe and weld. A test scheme is proposed for further testing by both sides.

Detecting Workpiece Information

Detection Objects Name Carbon Steel Straight Welded Pipe (High Frequency Welding)

Material Metal materials such as ferromagnetic materials

Dimension Specification Φ12-108mm

Weld Width 1-5mm (Flat weld or burr)

Length On-line detection

Bending Degree 1.5mm/m (Of the detection station)

Roughness Round surface (chamfered end without convex burr)≦3.2, no oxide scale.

Hardness Harder

Detection Speed Recommended through speed≦150m/min Adjustable

(Instrument detection speed: 0.52-750m/min)

Detection Part Temperature ≦80°C or normal temperature

Detection Requirement and Accuracy Standard

Executive Standard of Detection

Number of Standard Name of Standard Grade

GB/T 14480-2015 Nondestructive Testing Instrument Eddy Current Testing Equipment /

GB/T 7735-2016 Automatic eddy current testing for seamless and welded steel pipe The Highest Grade

(except submerged arc welding) defects

Technical Parameter of the System

Name of the System: On-line eddy current testing system for straight welded pipe

Type: EFH1002

Detection Method: Dual channel saddle detection (Absolute + Differential)

Control Mode: Automatic + Manual

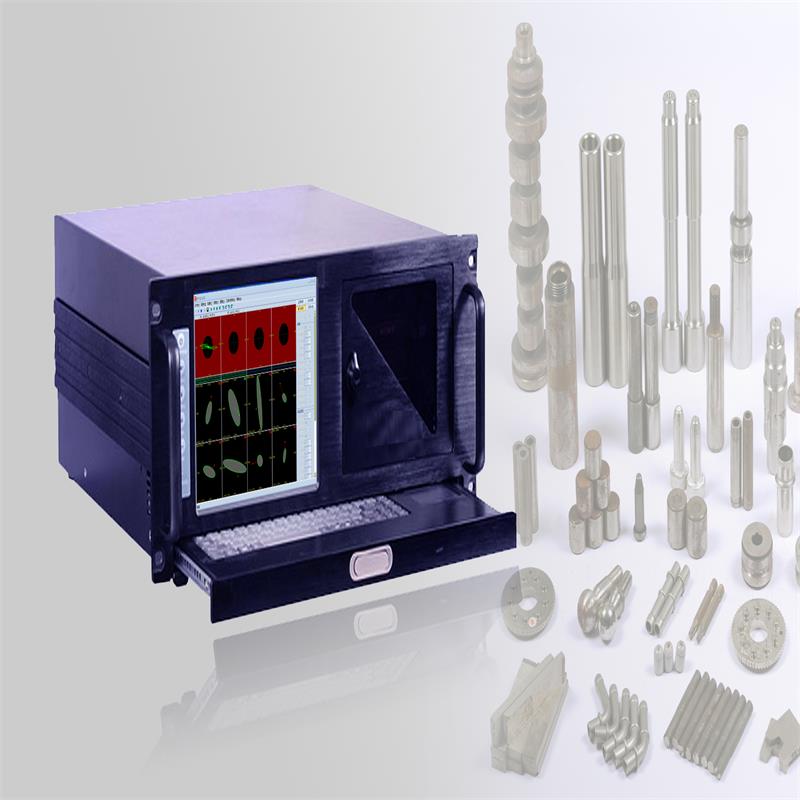

Instrument and Probe: Eddy current instrument; Dual Channel Digital High Intelligence Eddy Current Flaw Detector and Probe

Detection Platform: Core detection platform independently developed

Brief Introduction of Detection Operation:

Adjust the technical parameters and standard samples of flaw detector according to the testing requirements;

Adjust the position of probe and probe according to workpiece specifications;

The flaw detection system detects the workpiece, alarms and marks;

The welding head can be ground or adjusted by shutdown during the process;

Data recording, storage and analysis are carried out by the flaw detection host;

Automatically form flaw detection report.

Important Parameters of the System

Name Technical Parameter Remarks

End Blind Area ≦50m Depending on the test speed

Stability After 72 hours≦2dB Test sample

Accuracy of Jet Printing ±50mm Test sample

Omissive Judgement Rate 0% Test sample

Misreporting Rate ≦2% Test sample

Test Speed Recommended through speed≦150m/min Test sample

Adjustable (Instrument detection speed: 0.52-750m/min)

Principle of Laid/Saddle Type Eddy Current Testing

This system is used for eddy current detection of carbon steel, stainless steel, copper, aluminum and other non-ferrous and ferrous metal pipes. The whole system consists of five parts: detection device, detection accessories, machinery, electricity and pneumatic. Impedance plane analysis and multi-amplitude phase area alarm technology are used to realize automatic defect detection and output automatic sorting signal, alarm and marking signal.

The alternating current generated by the instrument produces eddy current on the surface of the workpiece through the detection coil, and the magnetic field generated by the eddy current affects the impedance of the detection coil in turn. When there are defects on the surface of the workpiece and the material is not continuous, the original eddy current field will be destroyed and the impedance of the detection coil will be changed. The instrument feeds back to the measuring probe. Impedance change electrical signal is processed to realize automatic defect detection.

General Description of the System

The online system includes: intelligent digital dual-channel flaw detector, customized detection device, probe, alarm system, marking system, customized genuine detection software, automatic control module (integration), customized shielding cabinet and other standard accessories.

WEHANS AUTOMATION TECHNOLOGY. CO., LTD

Contact Person: Cynthia

Telephone: +86 15062667823

Landline: +86 18121053868

Company Address: Building 1, No. 268, Dengyun Road, Yushan Town, Kunshan City, JIangsu Province, China.

Website: www.wehans-tech.com

Previous: On-line eddy current testing syst...

-

Multi-channel intelligent digital eddy current detector EIG3000

-

Multi frequency& multi-channel intelligent digital eddy current detector EK3000

-

Multi-channel intelligent digital eddy current detector EIG2000

-

Intelligent digital eddy current material sorting instrument ERS6000

-

On-line eddy current testing system for stainless steel straight welded pipe ECN1002/EFN1002

-

On-line eddy current testing system for straight welded pipe EFH1002

-

On-line eddy current testing system for spring steel wire ECH7002

-

PCB Metallographic Microscope (JX22/JX23-RT)