Products

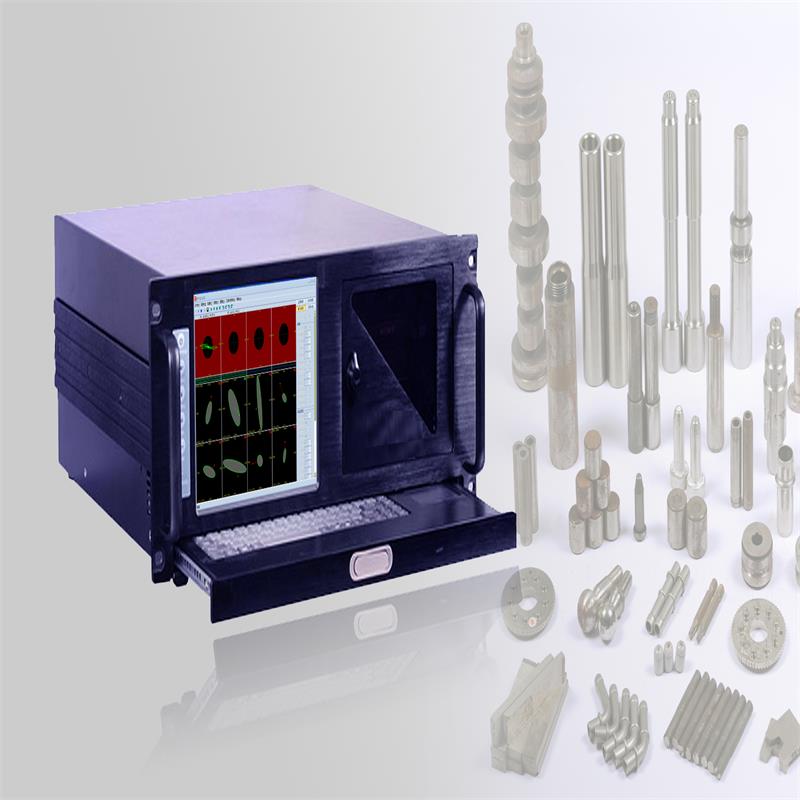

Intelligent digital eddy current material sorting instrument ERS6000

Five Advantages Of Products

- New Hardness Material Sorting Technology of Multi-frequency + Multi-channel Heat Treatment

- Rapid sorting of material hardness, heat treatment, tensile strength, structure, sintering density of mixtures, non-destructive testing, no damage to parts and materials.

- The new software algorithm, better detection performance and higher noise-to-noise ratio than the peers, continuous software development, providing free software upgrades for life.

- Has a single channel 8-frequency sorting function, and it can also work at 8 frequencies for multiple channels at the same time.

- Powerful software features include parameter storage, data storage, report analysis, statistics and more.

Product Details

Intelligent digital eddy current material sorting instrument

New Hardness Material Sorting Technology of Multi-frequency + Multi-channel Heat Treatment

◆ ERS6000 series intelligent digital eddy current material sorting instrument is especially suitable for hardness sorting and testing of automobile/aviation parts materials in heat treatment.

◆ Rapid sorting of material hardness, heat treatment, tensile strength, structure, sintering density of mixtures, non-destructive testing, no damage to parts and materials. Really realize 8 frequency simultaneous detection, higher detection accuracy, stability and reliability than single frequency detection. Eliminate the possibility of missed detection of all differences.

◆ The new software algorithm, better detection performance and higher noise-to-noise ratio than the peers, continuous software development, providing free software upgrades for life.

◆ Has a single channel 8-frequency sorting function, and it can also work at 8 frequencies for multiple channels at the same time.

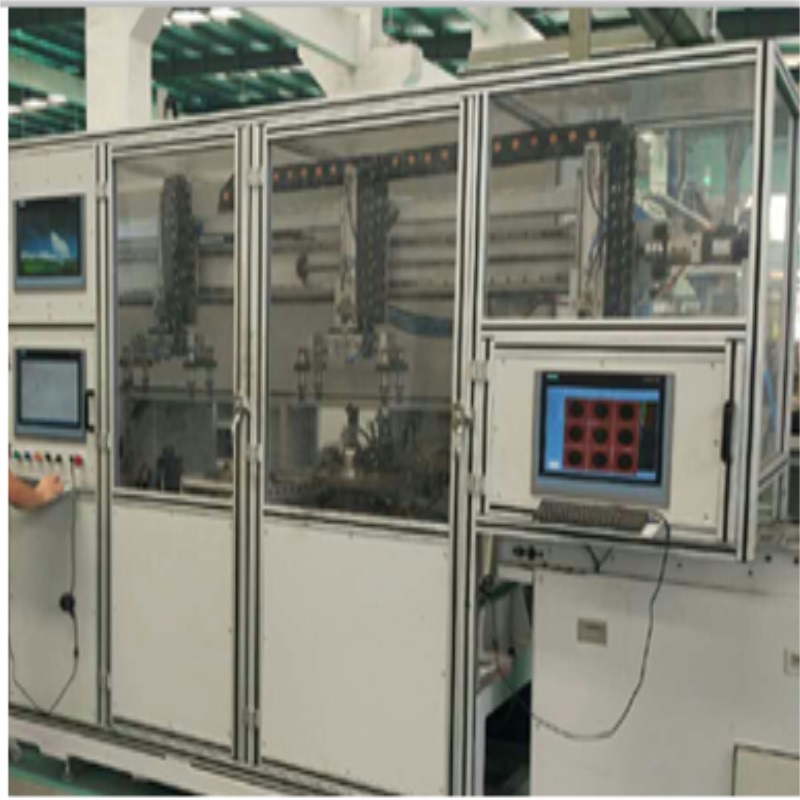

◆ Can customize different kinds of probes according to customer’s testing requirements. It can be manually tested in the laboratory or integrated with automated mass rapid detection. Has many kind of I/O data interfaces, can realize the functions of fast automatic detection, automatic sorting, automatic alarm, automatic statistics, etc.

◆ Powerful software features include parameter storage, data storage, report analysis, statistics and more.

◆ The instrument is simple, reasonable and intuitive to operate.

◆ Quickly switch between Chinese and English with one button, and quickly customize multi-language packs.

8 Frequency Sorting of Hardness/Material/Heat Treatment/Shape Difference and More

Detection Method Detection Quantity Known OK NG Undetected NG Items

Metallographic Analysis 2000 1884 116 0

Ordinary Single Frequency Detection 2000 1884 81 35

Multi-frequency Detection 2000 1884 116 0

Technical Specifications

◆ Detection channel: 1-16 (sustainable expansion of 256 channels as needed)

◆ Frequency range: 10 Hz~12MHz, continuously adjustable; multiple independent frequencies, single frequency, 8 frequency options (up to 16 software frequencies per channel);

◆ The system is based on WINDOWS development, and the system is permanently upgraded for free;

◆ Gain range: 0.0dB~99.0dB continuously adjustable, stepping: 0.1dB; fine-tuning, fast increase/decrease;

◆ Gain ratio: (X/Y) 0.1~10.0; continuously adjustable, fine-tuning, fast increase/decrease;

◆ Signal to noise ratio≥10dB (up to 30db);

◆ Phase rotation: 0~360° continuously adjustable; Stepping: 1;

◆ Adjustable probe drive (excitation) level: 1 to 16 ;

◆ Filter coefficient:0-30000;

◆ Adjustable detection range, ie maximum measurement value: 10~10000, step 1;

◆ Hardware amplification factor: 1dB ~ 32dB continuously adjustable, step: 1dB;

◆ Multiple excitation modes: DP/DI; can be configured with differential, absolute and various custom probes.

◆ Probe abnormal alarm function (viewing model)

◆ Fast digital balance;

◆ The solid line and blanking display modes are flexible and optional;

◆ Blanking display coefficient: 1~400;

◆ Digital filtering: low-pass (0Hz~2000Hz) high-pass (0Hz~2000Hz); using a unique "digital filtering" to effectively suppress the on-site interference signal, to ensure the accuracy and stability of the detection;

◆ Stability: 16 hours≤2dB;

◆ The utility model has the function of cutting off the end and end tail signals, and effectively controlling the end dead zone of the end end;

◆ The alarm duration can be adjusted: 10ms~60,000ms, stepping 1ms;

◆ Missing rate:≤0%, false positive rate (falsely judged as a non-conforming product by mistake)≤1%;

◆ Provide accurate and timely feedback signals to the defect parts, and perform inkjet marking, marking position, length, etc. (requires peripheral support);

◆ Automatically record the number of defects and their locations;

◆ With delay marking, fixed length marking, delay alarm and other functions;

◆ Flexible internal and external clock selection

◆ Marking accuracy up to ≤±10mm (requires peripheral support, depending on detection speed, requirements);

◆ Real-time software/hardware output alarm, multiple alarm window modes (circular, square, fan-shaped, custom type), with alarm, pre-alarm function, and can output signals separately;

◆ Non-equal amplitude, asymmetric phase alarm zone setting;

◆ Multiple display modes: impedance, time base, A\B sweep, 8 frequency sorting, analog 3D display (depending on model selection);

◆ With a unique time base alarm reference line, more intuitive detection data display.

◆ Can store a large number of various detection programs and test data;

◆ The eddy current signal playback extension function can measure the amplitude, phase and digital value of the defect;

◆ Cartesian coordinate system and polar coordinate system background selection;

◆ Automatically form test reports (including the number of tests, test personnel, test parameters, number of pass and number of non-conformities, etc.);

◆ One-click switching between Chinese and English operating languages, no need to install an operating system or online help;

◆ Working environment: Power supply: AC 220V/110V;

◆ Working temperature: 0°C ~ +45°C, storage temperature: -20°C ~ +50°C, relative humidity: ≤ 85%;

◆ The plane for installation of each flaw detector is: 550×1000mm2, and the signal line can be either side wall or bottom.

◆ Appearance size and weight: 500*500*260mm (L*W*H), weight: 5kg. (without display)

◆ Optional small industrial control type, horizontal industrial control type, 5U industrial control type (with display)

WEHANS AUTOMATION TECHNOLOGY. CO., LTD

Contact Person: Cynthia

Telephone: +86 15062667823

Landline: +86 18121053868

Company Address: Building 1, No. 268, Dengyun Road, Yushan Town, Kunshan City, JIangsu Province, China.

Website: www.wehans-tech.com

Previous: Multi-channel intelligent digital...

-

Multi-channel intelligent digital eddy current detector EIG3000

-

Multi frequency& multi-channel intelligent digital eddy current detector EK3000

-

Multi-channel intelligent digital eddy current detector EIG2000

-

Intelligent digital eddy current material sorting instrument ERS6000

-

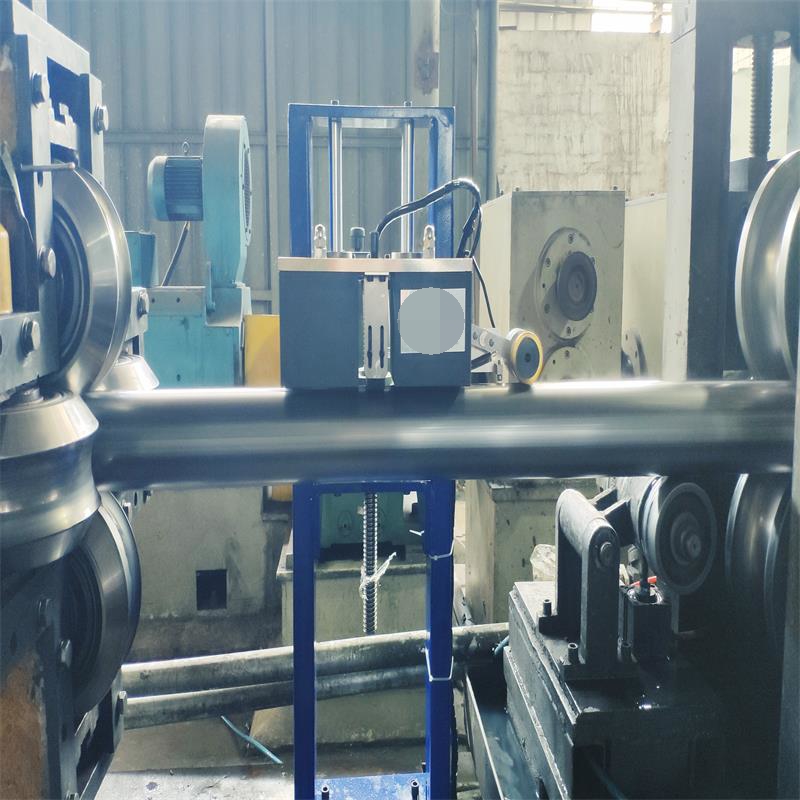

On-line eddy current testing system for stainless steel straight welded pipe ECN1002/EFN1002

-

On-line eddy current testing system for straight welded pipe EFH1002

-

On-line eddy current testing system for spring steel wire ECH7002

-

PCB Metallographic Microscope (JX22/JX23-RT)