Products

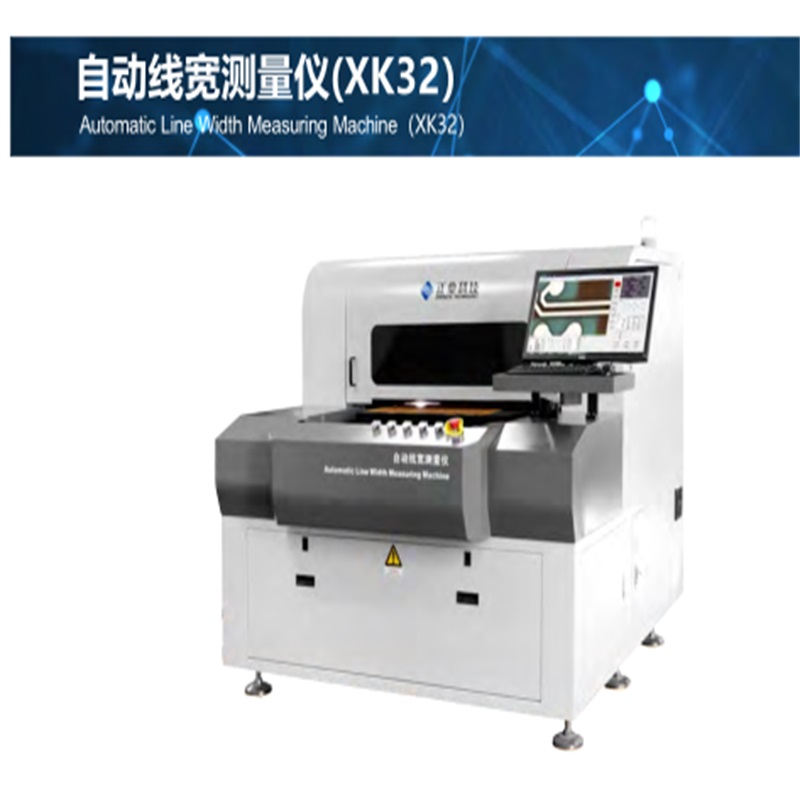

PCB Automatic Line Width Measuring Machine (XK32)

Five Advantages Of Products

- 1. Automatic positioning measurement: The user can import the DXF data, and customize the measurement location information according to the DXF file, generate an automatic measurement program and then import the software for automatic measurement;

- 2. Auto focus: When the automatic measurement is performed, the imaging system automatically focuses to ensure that the measurement position is clear and accurate;

- 3. Automatic switching magnification: Automatic zoom lens, no manual switching, software online switching magnification;

- 4. Navigation Positioning: Navigation image positioning function;

- 5. Automatic edge search: Automatically grasp the line, width of upper and lower lines, line spacing, round diameter, etc. during automatic measurement;

Product Details

PCB Automatic Line Width Measuring Machine (XK32)

USAGE

The automatic line width measuring instrument XK32 is suitable for detecting the widths of the upper and lower webs of the inner and outer layers of the PCB after etching (before the green oil), as well as the distance between the etching lines and the copper lines, the hole-to-edge distance, and the round holes blind hole diameter, etc.; and suitable for line width measurement of IC wafers and LCDs.

CHARACTERISTICS

Data statistics function: EXCEL data archiving and statistics functions; data automatically exported;

SPC statistics: capable of SPC statistical analysis;

Self-developed wire width measurement software, support MES database docking: support SQL database docking and realize factory informatization.

TECHNICAL PARAMETER

ITEM XK32

Parameters Dimension 1810×2070×1700mm

Equipment Equipment Capacity Measurement of (line width/ line spacing/ width of upper and lower

Capacity Measurement Project lines/ round diameter/ Goldfinger line width/ pads/ SMT-PAD/ etc.)

within view of camera after developing and etching the inner and outer

layer of the PCB.

Measuring Range of 720mm×700mm (platform measurement range can be customized)

Platform (W×L)

Table Surface Adsorption platform+Edge positioning

Plate Thickness Range 0.036mm-6mm

Measuring Range 10μm-3100μm

of Line Width

Precision of Line 1x=±3μm; 2x=±2μm; 3x=±1μm; 4x=±1μm; 4.5x=±1μm

Width Measurement

Imaging System Camera 5 million gigabit color CCD

CCD Resolution 2560×1920pixel

Lens 0.7x~4.5x continuous automatic lens doubling

Different Magnification 1.0x-2.3μm/pixel; 2.0x-1.5μm/pixel;

/Image Resolution 3.0x-0.9μm/pixel,4.0x-0.7μm/pixel; 4.5x-0.5μm/pixel

Measuring Repeatability ±2 pixel

Measurement Window Minimum Magnification

Field of View 0.7X=X3.50mm-Y2.65mm

Maximum Magnification

4.5X=X0.75mm-Y0.55mm

(View Deviation Range: ±5%)

Light Source Annular LED (Brightness can be continuously adjusted)

Separate dual-annular light source at the top and bottom

Navigation Field of Vision X1.2mm-Y0.8mm

The Navigation and

Positioning Camera Equipped with CCD navigation, which is convenient and fast to

locate the measurement target.

Autofocus Software autofocus

Operation Mode Learning Mode Learn from the first article as the programming model, operating the measurement

automatically.

CAM Data Import Mode Support Genesis 2000 exporting GBR-RX274 format data and using GBR format to

import data into software, program the first article through layers data and operate

the measurement.

Measuring Edge Finding method has manual and automatic edge-finding function.

Measurement Speed 3S/point

Data Output Data Export Export EXCEL data automatically and store it in the specified path.

Statistics Function

Database Sharing Has SQL database sharing and can dock with MES information terminal.

Installation Environmental No contact with acid, base, corrosive gas or liquid.

Requirements Note: Damage due to corrosive environment is not within the warranty scope.

WEHANS AUTOMATION TECHNOLOGY. CO., LTD

Contact Person: Cynthia

Telephone: +86 15062667823

Landline: +86 18121053868

Company Address: Building 1, No. 268, Dengyun Road, Yushan Town, Kunshan City, JIangsu Province, China.

Website: www.wehans-tech.com

Previous: On-line PCB Thickness Inspector (...

-

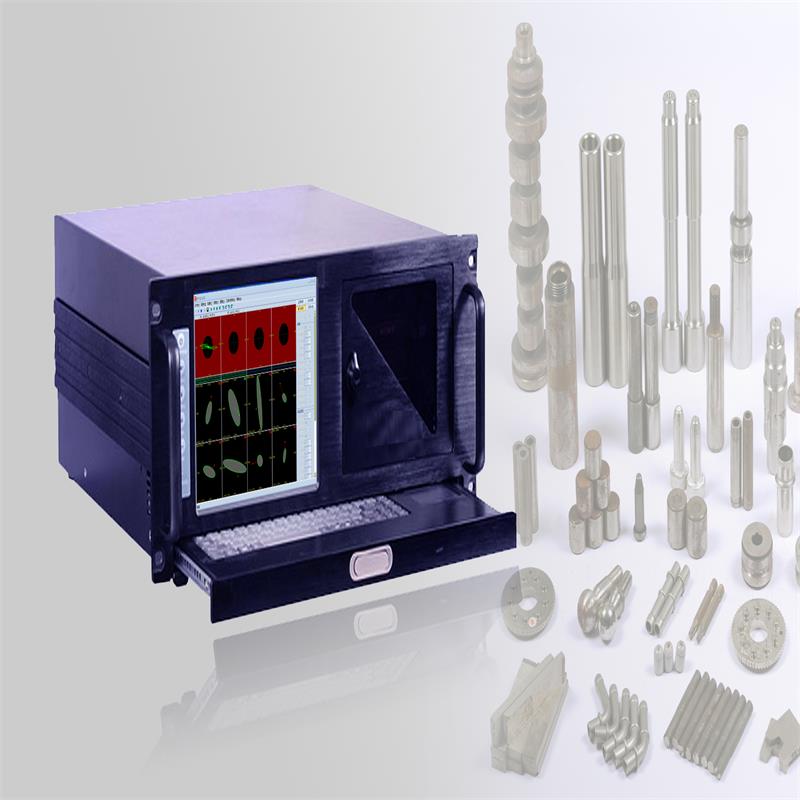

Multi-channel intelligent digital eddy current detector EIG3000

-

Multi frequency& multi-channel intelligent digital eddy current detector EK3000

-

Multi-channel intelligent digital eddy current detector EIG2000

-

Intelligent digital eddy current material sorting instrument ERS6000

-

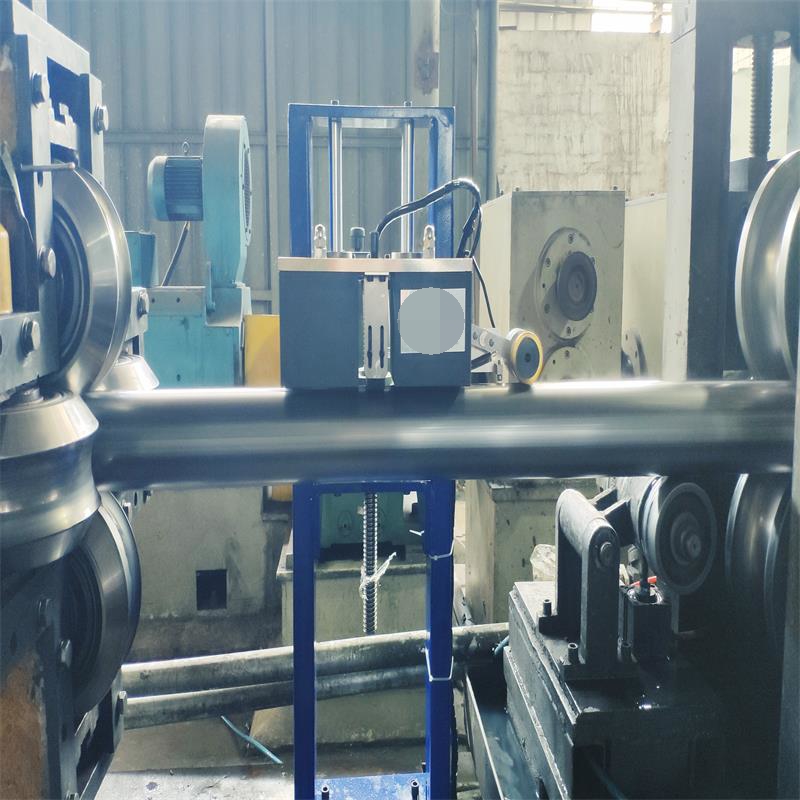

On-line eddy current testing system for stainless steel straight welded pipe ECN1002/EFN1002

-

On-line eddy current testing system for straight welded pipe EFH1002

-

On-line eddy current testing system for spring steel wire ECH7002

-

PCB Metallographic Microscope (JX22/JX23-RT)