Products

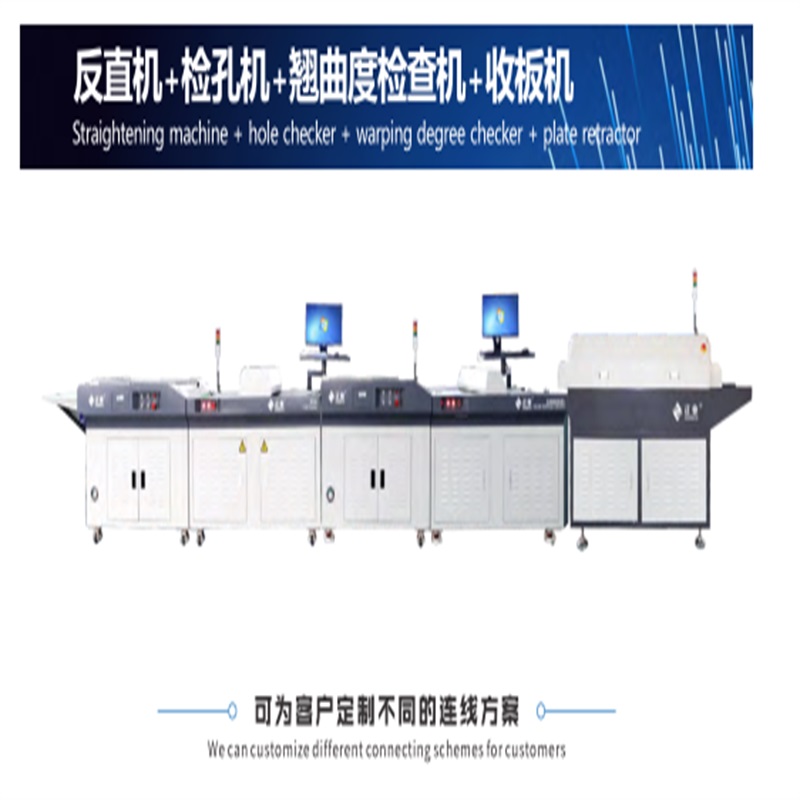

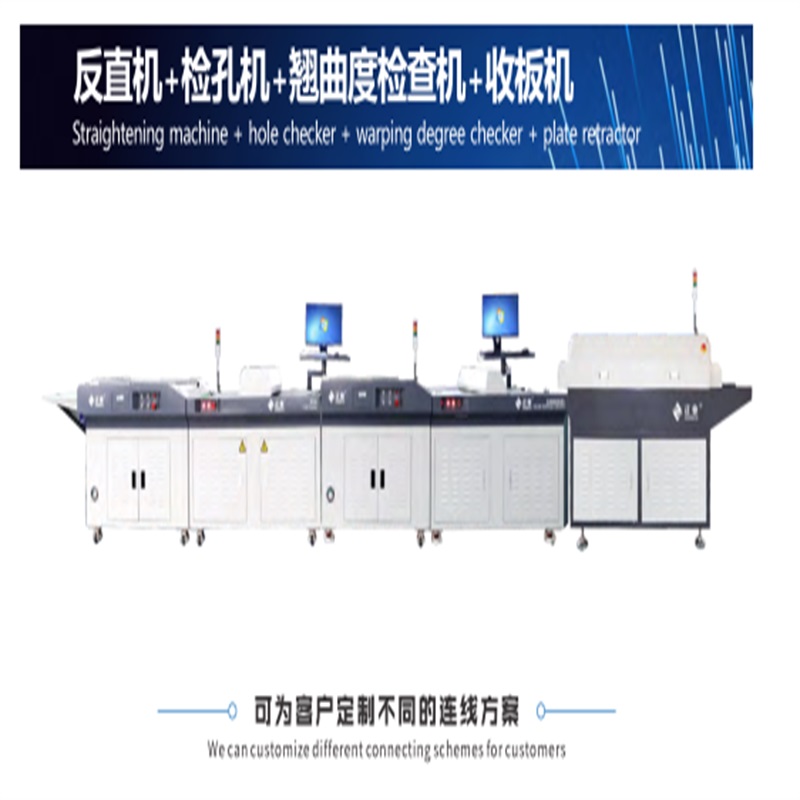

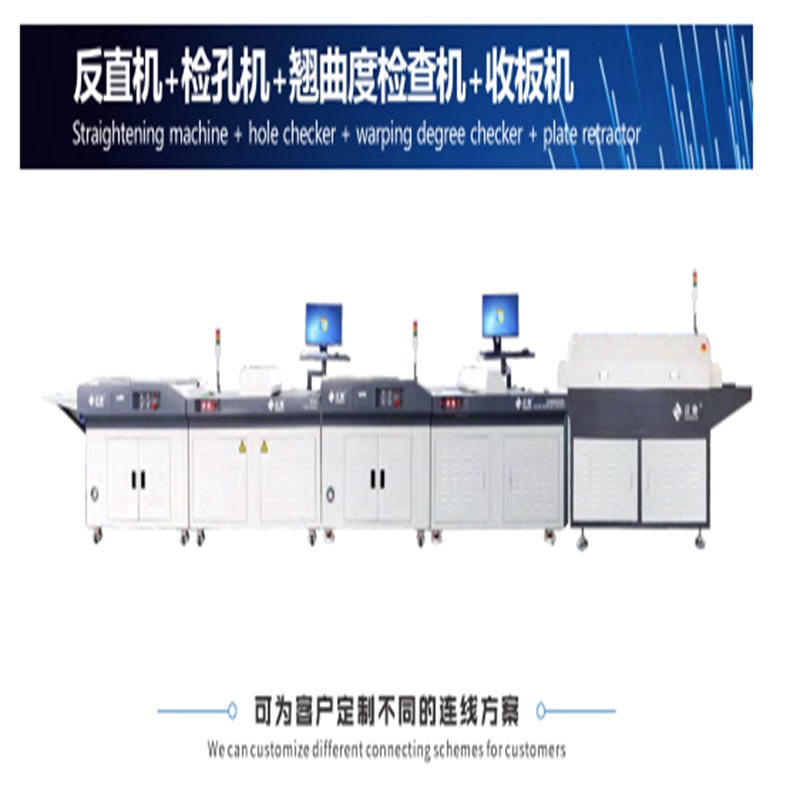

PCB Straightening Machine + Hole Checker + Warping Degree Checker + Plate Retractor

Five Advantages Of Products

- The horizontal warping and straightening machine is mainly used for quick leveling of PCB finished boards, such as bending, warping and deformation.

- Hole checker is suitable for hole quality inspection and analysis of PCB drilling boards and finished boards.

- Detection contents: automatic detection of defects such as few holes (drill leakage, plug hole), multiple holes (drill more, split in two), foreign bodies inside the holes, large holes, small holes, length, width. Angle of “one” type slot holes and other irregular shaped holes.

- Warping degree checker is mainly used in PCB finished board or copper clad board “board bending, board warping, deformation” . Defects are checked for quality and warpage values are analyzed.

- The board receiver classifies the equipment according to OK/NG signals sent by the detection equipment.

Product Details

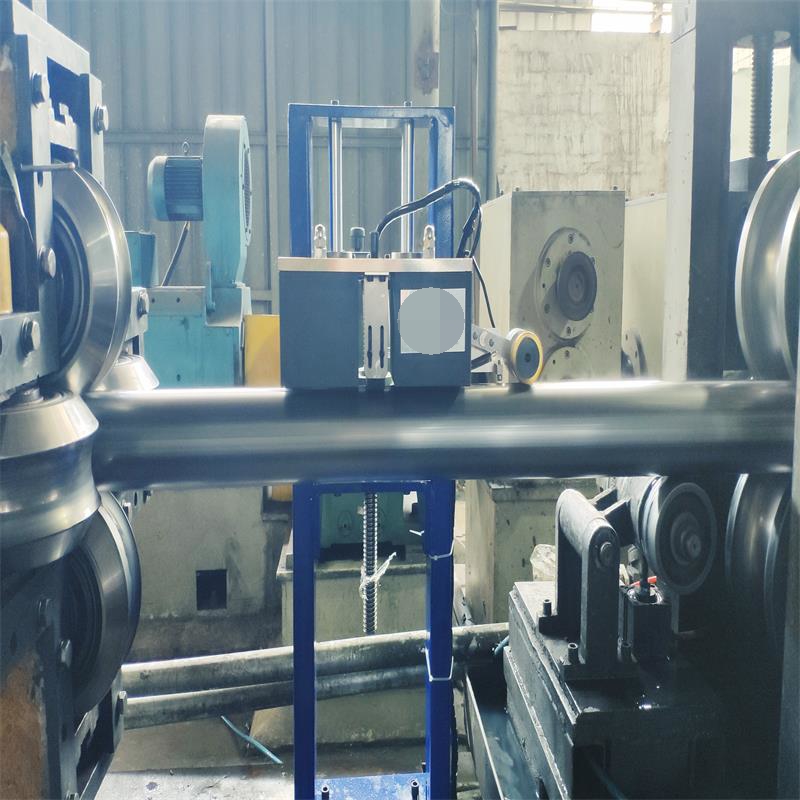

Straightening Machine + Hole Checker + Warping Degree Checker + Plate Retractor

USAGE

1. The horizontal warping and straightening machine is mainly used for quick leveling of PCB finished boards, such as bending, warping and deformation.

2. Hole checker is suitable for hole quality inspection and analysis of PCB drilling boards and finished boards.

Detection contents: automatic detection of defects such as few holes (drill leakage, plug hole), multiple holes (drill more, split in two), foreign bodies inside the holes, large holes, small holes, length, width. Angle of “one” type slot holes and other irregular shaped holes.

3. Warping degree checker is mainly used in PCB finished board or copper clad board “board bending, board warping, deformation” .

Defects are checked for quality and warpage values are analyzed.

4. The board receiver classifies the equipment according to OK/NG signals sent by the detection equipment.

WEHANS AUTOMATION TECHNOLOGY. CO., LTD

Contact Person: Cynthia

Telephone: +86 15062667823

Landline: +86 18121053868

Company Address: Building 1, No. 268, Dengyun Road, Yushan Town, Kunshan City, JIangsu Province, China.

Website: www.wehans-tech.com

Previous: PCB UV Laser Cutting Machine (JG15C)

-

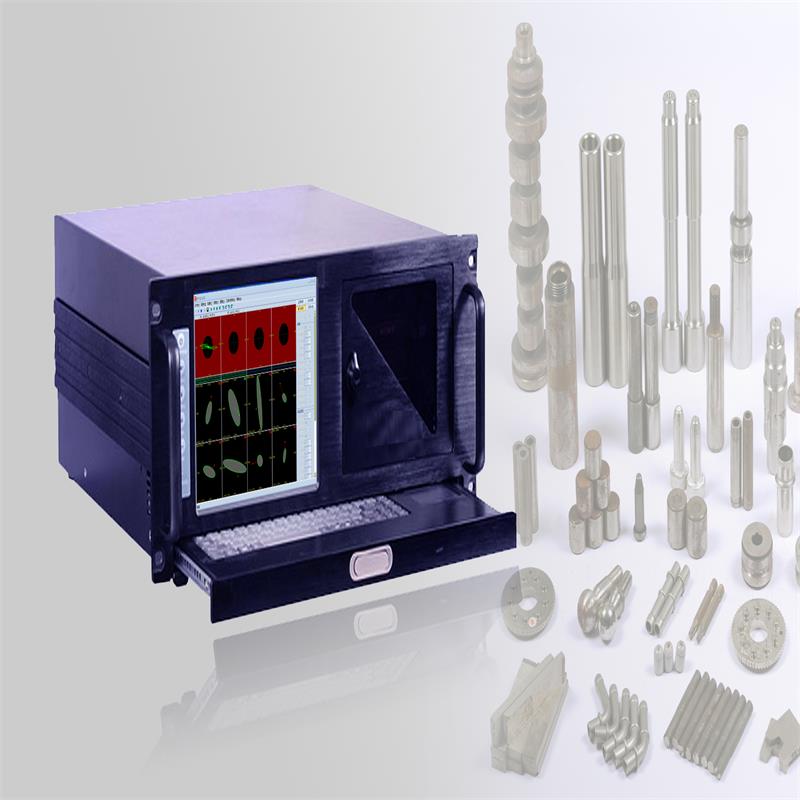

Multi-channel intelligent digital eddy current detector EIG3000

-

Multi frequency& multi-channel intelligent digital eddy current detector EK3000

-

Multi-channel intelligent digital eddy current detector EIG2000

-

Intelligent digital eddy current material sorting instrument ERS6000

-

On-line eddy current testing system for stainless steel straight welded pipe ECN1002/EFN1002

-

On-line eddy current testing system for straight welded pipe EFH1002

-

On-line eddy current testing system for spring steel wire ECH7002

-

PCB Metallographic Microscope (JX22/JX23-RT)