Products

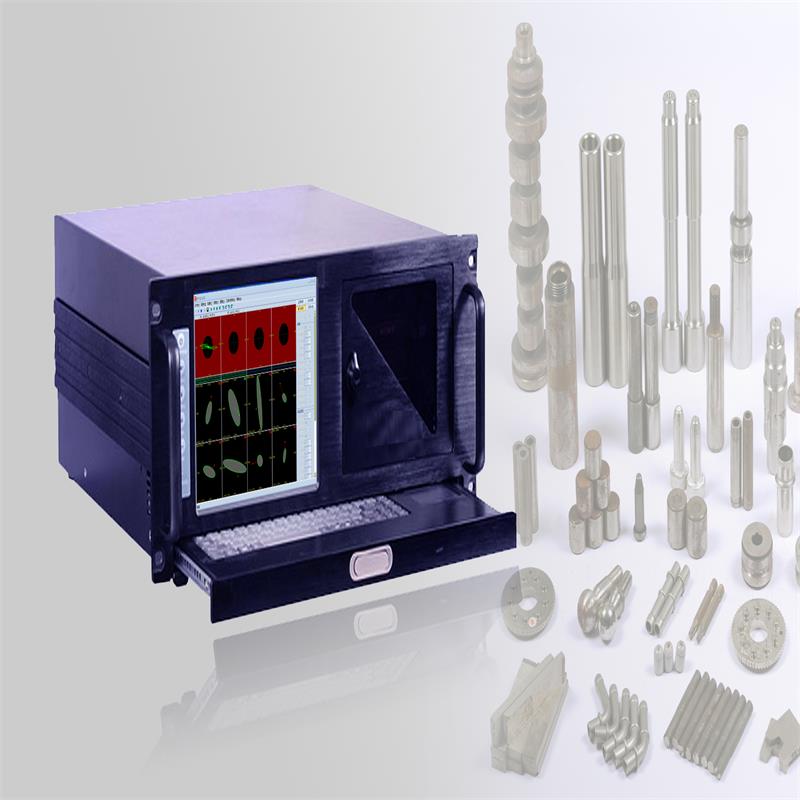

On-line eddy current testing system for Combined drawing machine ECN8002

Five Advantages Of Products

- Adjust the technical parameters and standard samples of flaw detector according to the testing requirements.

- Adjust the position of probe and probe according to workpiece specifications.

- The flaw detection system detects the workpiece, alarms and marks.

- Data recording, storage and analysis are carried out by the flaw detection host.

- The OK/NG signal is output to the sorting system.

Product Details

On-line eddy current testing system for Combined drawing machine ECN8002

Project Overview

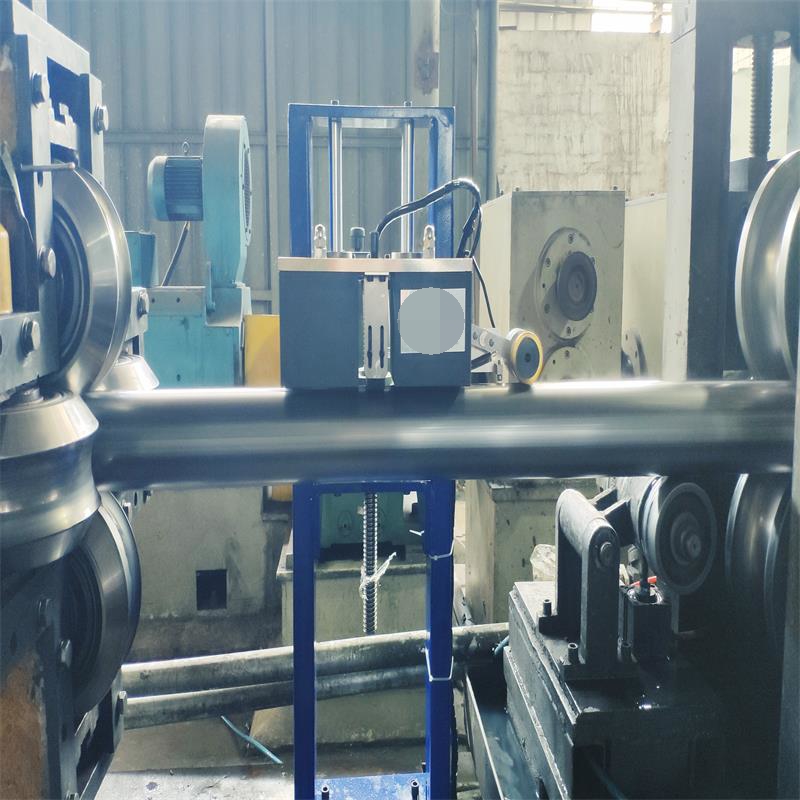

Customers produce drawing bars, mainly made of non-ferrous or ferrous metals. It is planned to install an on-line eddy current testing system on the combined drawing machine, and the OK/NG material will be sorted by the output signal after testing. The program will be proposed according to customer's product specifications and testing requirements. The actual design is different from the plan pictures, but the deviation is small. The design review drawings shall prevail.

1.1The material is non-ferrous metal, which can be detected by ordinary through probe.

1.2The material is ferromagnetic material. The uneven distribution of magnetic field in the material results in the instability of eddy current detection signal. The eddy current detection is based on magnetic saturation technology. After the detection, the demagnetization device is used to demagnetize (if necessary).

On the selection of installation position of on-line eddy current testing platform for combined drawing machine: because of the vibration of the position after shearing, it is impossible to install the testing platform, and the bar rotation in the two-roll position is not suitable for installation. Considering the factors of vibration and uniform speed, it is installed in the position of cross-straightening and vertical straightening before shearing.

The solution to the difficulty of correct sorting after shearing: through the signal of shearing machine, encoder and other signals, it can accurately identify the subsequent outflow bar (after shearing).

Other field requirements: the flaw detection system requires the puller to cut off the mechanism signal, the speed code signal can be output to the flaw detection system, in order to achieve accurate OK/NG sorting after cutting off. The number of photoelectric resolving elements (there is a clear gap between the continuously flowing rod and the rod) and the signal of clamping wheel can be used to separate the rod after cutting.

Ensure that the installation position is about 600mm in the axial direction before cutting off, the workpiece's jumping circumference is within ±0.1mm, the head of the bar should be introduced manually to avoid breaking the probe mechanism, and the tail should be cut off manually and pulled out after warping, so as to avoid damaging the probe.

Detecting Workpiece Information

Detection Objects Name Non-ferrous metal tubes, bars (non-ferrous metals such as aluminium and copper), ferrous metal bars, etc.

Material Nonferrous metals, ferrous metals, etc.

Dimension Specification: 8mm

Weld Width /

Length On-line flaw detection of length, flying saw cutting pipe or coil after flaw detection

Bending Degree 1.5mm/m (Of the detection station)

Circular Degree Circular tube≦0.1mm

Roughness Pipe wall and weld (with burrs)≦3.2, bar without protruding burr, etc.

Hardness Harder

Detection Speed ≈60m/min (Instrument detection speed: 0.52-750m/min)

Detection Part Temperature ≦80°C or normal temperature

Detection Requirement and Accuracy Standard

Executive Standard of Detection

Number of Standard Name of Standard Grade

GB/T 14480-2015 Nondestructive Testing Instrument Eddy Current Testing Equipment /

GB/T 11260-2008 Eddy Current Testing Method for Round Steel /

GB/T 29997-2013 Eddy Current Testing Method for Copper and Copper Alloy Bars and Wires /

Technical Parameter of the System

Name of the System: On-line eddy current testing system for Combined drawing machine (Cut off Precise Sorting Series)

Type: ECN8002

Detection Method: Dual Channel Through Type Detection (Absolute + Differential)

Control Mode: Automatic + Manual

Instrument and Probe: Eddy current instrument; Dual Channel Digital High Intelligence Eddy Current Flaw Detector and Probe

Detection Platform: Core detection platform independently developed

Brief Introduction of Detection Operation:

Adjust the technical parameters and standard samples of flaw detector according to the testing requirements;

Adjust the position of probe and probe according to workpiece specifications;

The flaw detection system detects the workpiece, alarms and marks;

Data recording, storage and analysis are carried out by the flaw detection host;

The OK/NG signal is output to the sorting system;

Automatically form flaw detection report;

The probe can be quickly replaced. The replacement time is less than 120S.

Important Parameters of the System

Name Technical Parameter Remarks

End Blind Area ≦50m Depending on the test speed

Stability After 72 hours≦2dB Test sample

Accuracy of Jet Printing ±50mm Test sample

Omissive Judgement Rate 0% Test sample

Misreporting Rate ≦2% Test sample

Accurate Sorting Rate 100% Test sample

Test Speed Instrument detection speed: 0.52-750m/min Test sample

WEHANS AUTOMATION TECHNOLOGY. CO., LTD

Contact Person: Cynthia

Telephone: +86 15062667823

Landline: +86 18121053868

Company Address: Building 1, No. 268, Dengyun Road, Yushan Town, Kunshan City, JIangsu Province, China.

Website: www.wehans-tech.com

Previous: On-line eddy current testing syst...

Next: No

-

Multi-channel intelligent digital eddy current detector EIG3000

-

Multi frequency& multi-channel intelligent digital eddy current detector EK3000

-

Multi-channel intelligent digital eddy current detector EIG2000

-

Intelligent digital eddy current material sorting instrument ERS6000

-

On-line eddy current testing system for stainless steel straight welded pipe ECN1002/EFN1002

-

On-line eddy current testing system for straight welded pipe EFH1002

-

On-line eddy current testing system for spring steel wire ECH7002

-

PCB Metallographic Microscope (JX22/JX23-RT)