Products

PCB FPC Appearance Checker Series (AVI-600L/AVI-800Z/AVI-1000Z)

Five Advantages Of Products

- The AVI device builds a neural network, and the software has a function similar to that of human brain and has the function of deep learning. It can make different calculation results for the defects of different products and feedback the results;

- High detection rate, few false alarm points, only one person is needed to complete the whole line work, greatly saving labor cost of re-judgement;

- The equipment has strong universality, fast switching between different types of machines, direct extraction detection, no need to invest in tooling and jig, saving a lot of cost;

- The equipment structure is simple.

- The failure rate of the machine is almost zero, low maintenance cost, high equipment moving rate.

Product Details

FPC Appearance Checker Series

(AVI-600L/AVI-800Z/AVI-1000Z)

USAGE

This equipment is mainly used in the appearance inspection of flexible printed circuit board (FPC) and FPCA after SMT, which can be directly connected to the extraction plate inspection, and can be automatically loaded and unloaded.

CHARACTERISTICS

1. The AVI device builds a neural network, and the software has a function similar to that of human brain and has the function of deep learning. It can make different calculation results for the defects of different products and feedback the results;

2. High detection rate, few false alarm points, only one person is needed to complete the whole line work, greatly saving labor cost of re-judgement;

3. The equipment has strong universality, fast switching between different types of machines, direct extraction detection, no need to invest in tooling and jig, saving a lot of cost;

4. The equipment structure is simple, the failure rate of the machine is almost zero, low maintenance cost, high equipment moving rate.

TECHNICAL PARAMETER

ITEM SPECIFICATIONS

Dimensions (L×W×H) 1000×1400×1500mm

Measurable Board MIN 60×80mm MAX 450×500mm

Detection Accuracy ±1mm

Repeat Accuracy CPK≧1.33

The Detection Accuracy

of Defective Products less than 0.3%

The Equipment More than 90% and the product yield is high.

Pass-through Rate This index can be improved.

The False Alarm Rate

(Counting Points per PCS) less than 0.5 points/PCS

The Detection Efficiency 0.5S-1.5S/PCS

Detection Mode Direct extraction plate detection, after the detection of direct extraction plate shipment.

Personnel Only one OP online operation to complete the detection line, feeding,

reviewing and selecting defective products.

Dual Machine Line Detection Mode

Feeder→AVI Detect Positive→Flipper→AVI Detecting the Opposite Side→Track→VRS

WEHANS AUTOMATION TECHNOLOGY. CO., LTD

Contact Person: Cynthia

Telephone: +86 15062667823

Landline: +86 18121053868

Company Address: Building 1, No. 268, Dengyun Road, Yushan Town, Kunshan City, JIangsu Province, China.

Website: www.wehans-tech.com

Previous: PCB Guide Pin (Single/Double-Side)

-

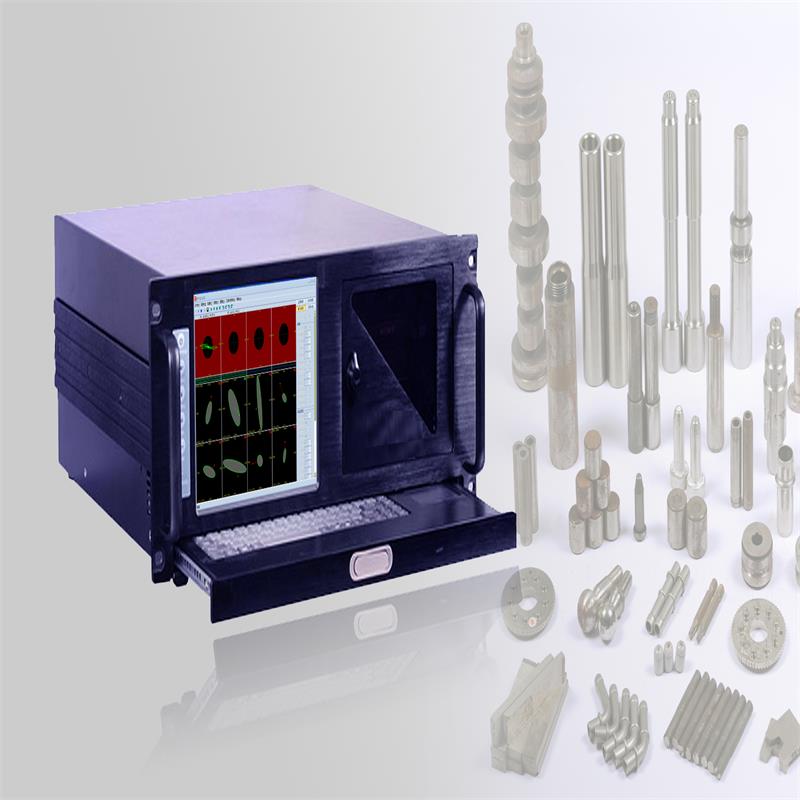

Multi-channel intelligent digital eddy current detector EIG3000

-

Multi frequency& multi-channel intelligent digital eddy current detector EK3000

-

Multi-channel intelligent digital eddy current detector EIG2000

-

Intelligent digital eddy current material sorting instrument ERS6000

-

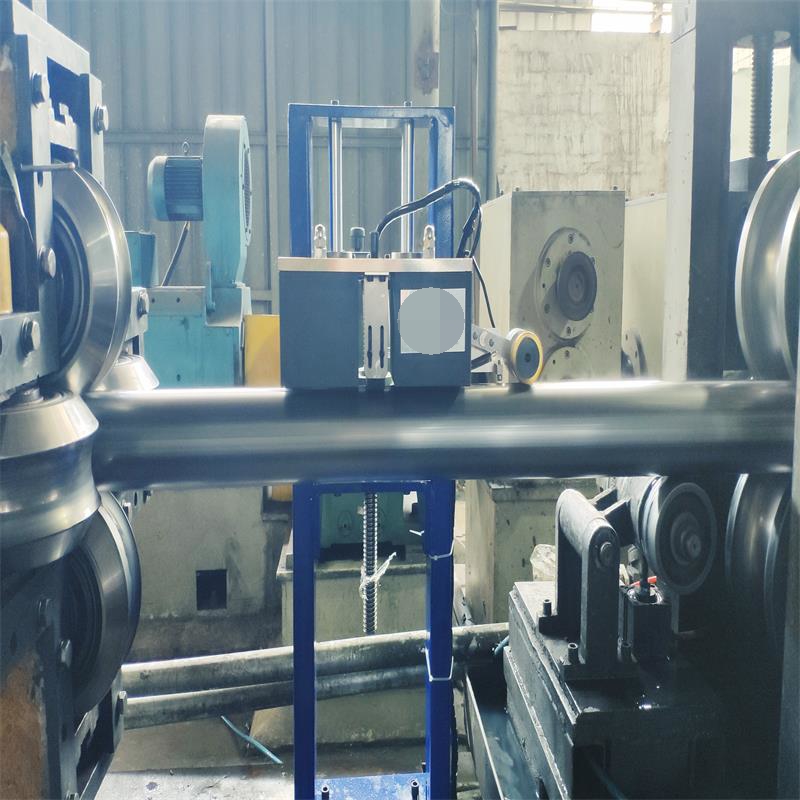

On-line eddy current testing system for stainless steel straight welded pipe ECN1002/EFN1002

-

On-line eddy current testing system for straight welded pipe EFH1002

-

On-line eddy current testing system for spring steel wire ECH7002

-

PCB Metallographic Microscope (JX22/JX23-RT)